|

Projects -

SUNDOG's Project Page

![]()

|

Here

is the project picture gallery from SUNDOG!

|

|

|

The vertical panel with the notch out of the corner was the original cover for the battery area. Now installed vertically into cabinet hasps, it covers the new and larger battery/wiring area. The cut out allows access to both the main switch and the 110v outlet mounted inside. |

|

The

Sonic leg has had the drain plug replaced with a stainless one

and all the Allen head

screws in the yoke replaced with hex heads with thin locking nuts.

The yoke bearings are now retained by the addition of bolts and

overlap washers to prevent the loss of the bearing materials from

being pushed out by grease pressure. A Sunbrella cover fastened

with Velcro protects the upper bellows gaiter from UV damage.

The white notched piece of high density polyethylene (HDPE) is

attached to the mounting plate and engages the square boss on

the top of the leg casting to keep the leg centered while in the

"up" position.

screws in the yoke replaced with hex heads with thin locking nuts.

The yoke bearings are now retained by the addition of bolts and

overlap washers to prevent the loss of the bearing materials from

being pushed out by grease pressure. A Sunbrella cover fastened

with Velcro protects the upper bellows gaiter from UV damage.

The white notched piece of high density polyethylene (HDPE) is

attached to the mounting plate and engages the square boss on

the top of the leg casting to keep the leg centered while in the

"up" position. |

This

view illustrates an additional Genoa track lower and outboard

of the stock one. This new sheeting point is an important choice

in certain wind conditions, where the "slot" needs to be more

open. Both upper and lower tracks are fitted with custom-built

Harken blocks that open like snatch-blocks to allow the jib sheets

to be easily shifted. This

view illustrates an additional Genoa track lower and outboard

of the stock one. This new sheeting point is an important choice

in certain wind conditions, where the "slot" needs to be more

open. Both upper and lower tracks are fitted with custom-built

Harken blocks that open like snatch-blocks to allow the jib sheets

to be easily shifted. |

This

is a view into the area above the stock battery compartment. SUNDOG

now carries two 6-volt Trojan fork-lift batteries (L-16s) as the

house bank. All stock wiring was removed and re-done with proper

fusing and larger grades of wire as shown. Electrical up-grades

included a larger alternator, dedicated starting battery and the

LINK 2000R control system. This

is a view into the area above the stock battery compartment. SUNDOG

now carries two 6-volt Trojan fork-lift batteries (L-16s) as the

house bank. All stock wiring was removed and re-done with proper

fusing and larger grades of wire as shown. Electrical up-grades

included a larger alternator, dedicated starting battery and the

LINK 2000R control system. |

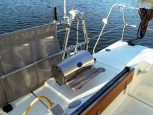

SUNDOG

supports her hard dodger with a custom-built marine aluminum arch

made by a fabricator who builds "Tuna towers" for fishing boats.

While being very strong, the entire unit weighs less than 10 pounds

and contains internal wiring for the LED

based overhead cockpit lights. SUNDOG

supports her hard dodger with a custom-built marine aluminum arch

made by a fabricator who builds "Tuna towers" for fishing boats.

While being very strong, the entire unit weighs less than 10 pounds

and contains internal wiring for the LED

based overhead cockpit lights. |

|

|

|

|

|

|

If

you have a factory installed fresh water stern shower, the attached

rubber cover will probably break off and fall overboard fairly soon.

The picture shows a cheap and robust replacement in the form of

a standard PVC plumbing piece that was turned down a little in a

lathe for a snug fit. It has a hole drilled in the top for a securing

line to stanchion base. If

you have a factory installed fresh water stern shower, the attached

rubber cover will probably break off and fall overboard fairly soon.

The picture shows a cheap and robust replacement in the form of

a standard PVC plumbing piece that was turned down a little in a

lathe for a snug fit. It has a hole drilled in the top for a securing

line to stanchion base. |

This

photo shows a hose connection where a dock water hose can be attached

to the boats internal fresh water system. It includes a pressure-reducing

valve to lower the dock pressure to 40 psi, which is safe for

the boat's plumbing. It is simply "Teed into the line feeding

the shower and allows you to operate off an endless supply of

fresh water while dockside. Do not ever leave the boat unattended

while using one of these…a blown off pipe fitting inside can flood

and sink your boat…turn it off on the dock whenever you leave

your boat unattended! This

photo shows a hose connection where a dock water hose can be attached

to the boats internal fresh water system. It includes a pressure-reducing

valve to lower the dock pressure to 40 psi, which is safe for

the boat's plumbing. It is simply "Teed into the line feeding

the shower and allows you to operate off an endless supply of

fresh water while dockside. Do not ever leave the boat unattended

while using one of these…a blown off pipe fitting inside can flood

and sink your boat…turn it off on the dock whenever you leave

your boat unattended! |

On

early 105's, all the external hatch latches were a Perko model designed

for use on bait well covers…they were never intended to be waterproof,

but could be fitted with an optional cover that helped a lot. We

choose to replace all of ours with a locking Perko model that is

fully waterproof…all can be keyed alike. The two top pictures show

the stock latches, with the right one showing the optional cover

in place. On

early 105's, all the external hatch latches were a Perko model designed

for use on bait well covers…they were never intended to be waterproof,

but could be fitted with an optional cover that helped a lot. We

choose to replace all of ours with a locking Perko model that is

fully waterproof…all can be keyed alike. The two top pictures show

the stock latches, with the right one showing the optional cover

in place.  The

picture below shows the fully waterproof and locking Perko model

in place…it is a little bigger, but not hard to retrofit. If you

have the older model latches, you will never have dry storage until

you replace them. The

picture below shows the fully waterproof and locking Perko model

in place…it is a little bigger, but not hard to retrofit. If you

have the older model latches, you will never have dry storage until

you replace them. |

|

The fuel line

taps in the existing propane locker (legal) and the flexible line

is easy to route aft above the |

When

the boat is stored, we use the "snap-on" canvas cover shown to secure

the instruments and cover the upper fridge vents. In port it can

be left on and rolled up to allow the fridge to work. When

the boat is stored, we use the "snap-on" canvas cover shown to secure

the instruments and cover the upper fridge vents. In port it can

be left on and rolled up to allow the fridge to work. |

We

use our asymmetrical chute quite a lot. It is a Melges 24 light

air chute that we picked up "on sale" from JSI. We had it installed

in an ATN "chute scoop" launch system, which works very reliably.

We tack it to a bridle, whose legs are then led through blocks attached

with a loop of lifeline cable to each bow cleat and led aft to a

winch. This enables us to shift the tack from side to side and required

no additional hardware to be permanently mounted to the boat. The

cable "loop" is thin enough to allow normal use of the cleat with

a mooring line. We

use our asymmetrical chute quite a lot. It is a Melges 24 light

air chute that we picked up "on sale" from JSI. We had it installed

in an ATN "chute scoop" launch system, which works very reliably.

We tack it to a bridle, whose legs are then led through blocks attached

with a loop of lifeline cable to each bow cleat and led aft to a

winch. This enables us to shift the tack from side to side and required

no additional hardware to be permanently mounted to the boat. The

cable "loop" is thin enough to allow normal use of the cleat with

a mooring line. |

Cover

those big windows…and they will last a lot longer without UV  damage damage

and

the inside of the boat will stay cooler when you run your AC in

the hot months. Local canvas shop made these that are attached with

snaps. We had all our canvas done in gray including the Genny and

Main covers. It's not that we don't like color, it's just that the

gray looks new forever…it's the only Sunbrella "color" that ages

without any visible change. and

the inside of the boat will stay cooler when you run your AC in

the hot months. Local canvas shop made these that are attached with

snaps. We had all our canvas done in gray including the Genny and

Main covers. It's not that we don't like color, it's just that the

gray looks new forever…it's the only Sunbrella "color" that ages

without any visible change. |

We

use a "soft" boom vang tackle attached to the Dutchman "Boom Brake".

This combo gives us a detachable vang/preventer and makes "power

jibes" safe and controllable. We

use a "soft" boom vang tackle attached to the Dutchman "Boom Brake".

This combo gives us a detachable vang/preventer and makes "power

jibes" safe and controllable. |

Late

model 105s have an engine driven hot water heater, but for those

of us with our trusty (?) gas Palomas, the screw opening Vetus deck

vent is prone to bending the single small shaft that holds the cover

on, if it is kicked or stepped on when open. The local metal shop

made this neat stainless "spider" that now protects that delicate

shaft. (0012) Late

model 105s have an engine driven hot water heater, but for those

of us with our trusty (?) gas Palomas, the screw opening Vetus deck

vent is prone to bending the single small shaft that holds the cover

on, if it is kicked or stepped on when open. The local metal shop

made this neat stainless "spider" that now protects that delicate

shaft. (0012) |

|

(2)

Mounted in the same cabinet as the AC unit is the heat exchanger

and blower fan for a Red-Dot "bus-heater" that uses engine heat

to warm the cabin when the engine is running…just like a car heater.

|

Good

turnbuckle covers can be easily (and cheaply!) fabricated from sections

of thin-wall PVC plumbing pipe. Put them on before you tune by sequentially

disconnecting each shroud and slide them up and over the turnbuckle

and re-connect. They can be taped out of the way up on the shroud

when you need to adjust the turnbuckle. Good

turnbuckle covers can be easily (and cheaply!) fabricated from sections

of thin-wall PVC plumbing pipe. Put them on before you tune by sequentially

disconnecting each shroud and slide them up and over the turnbuckle

and re-connect. They can be taped out of the way up on the shroud

when you need to adjust the turnbuckle. |

This

is one of a pair of "Sliphooks" that we use to be able to disconnect

the aft lowers and move them forward when running downwind. Available

from West-Diep Yachts in Holland : 058-23 92 48 is fax number, Attn:

Michel Paquet. This

is one of a pair of "Sliphooks" that we use to be able to disconnect

the aft lowers and move them forward when running downwind. Available

from West-Diep Yachts in Holland : 058-23 92 48 is fax number, Attn:

Michel Paquet. |

These

halyard bags were a West Marine product. We like them a lot for

keeping the lines and a winch handle. These

halyard bags were a West Marine product. We like them a lot for

keeping the lines and a winch handle. |

PVC

shroud rollers are sold in pairs…so one used to ease the genny around

the inner forestay when tacking will leave you with a spare…or one

to share. PVC

shroud rollers are sold in pairs…so one used to ease the genny around

the inner forestay when tacking will leave you with a spare…or one

to share. |

In

this mast photo, note the addition of a pair of double-line rope

clutches above the winches. These are invaluable in holding loaded

halyards and the topping lift to free up a winch drum or mast cleat

for another chore. The short track on the front of the mast is for

the whisker pole's use. Our sail cover is a modified UK "Lazy Cradle"

which is an integral sail cover system with lazy jacks. Unlike the

"Mack-Pack", it fully protects and covers both mast winches, rope

clutches and other mast mounted hardware. In

this mast photo, note the addition of a pair of double-line rope

clutches above the winches. These are invaluable in holding loaded

halyards and the topping lift to free up a winch drum or mast cleat

for another chore. The short track on the front of the mast is for

the whisker pole's use. Our sail cover is a modified UK "Lazy Cradle"

which is an integral sail cover system with lazy jacks. Unlike the

"Mack-Pack", it fully protects and covers both mast winches, rope

clutches and other mast mounted hardware. |

We

choose to discard the canvas cover over the hard dodger that fills

with rain and gets scummy. We glazed each opening with medium bronze

tint Plexiglas with the same methods used by the factory in the

installation of the other fixed windows. No pooling water, easy

to clean and you can see the sails through them now. We

choose to discard the canvas cover over the hard dodger that fills

with rain and gets scummy. We glazed each opening with medium bronze

tint Plexiglas with the same methods used by the factory in the

installation of the other fixed windows. No pooling water, easy

to clean and you can see the sails through them now. |

Later

model 105s have this access hatch to get to the area behind the

fridge. Note added clamshell vents in cover. We retrofitted this

one, as well as another one like it, in the aft bulkhead in the

bow storage locker, where there was no service access to the holding

tank as the boat was delivered (picture to the right). If your

boat does not have these hatches, the install is easy and the

access to both areas for service is mandatory. Later

model 105s have this access hatch to get to the area behind the

fridge. Note added clamshell vents in cover. We retrofitted this

one, as well as another one like it, in the aft bulkhead in the

bow storage locker, where there was no service access to the holding

tank as the boat was delivered (picture to the right). If your

boat does not have these hatches, the install is easy and the

access to both areas for service is mandatory. |

The

addition of the PVC pipe (schedule 40) on the aft edge of the hard-dodger

prevents accidental contact of the boom hardware with the new plex

windows up there and makes a secure hand rail as well. The

addition of the PVC pipe (schedule 40) on the aft edge of the hard-dodger

prevents accidental contact of the boom hardware with the new plex

windows up there and makes a secure hand rail as well. |

A

turning block was added to the roller furling termination at the

cockpit. It allows a fair lead for pulling up on the line (using

leg muscles)…much easier! This reefing line is led through added

ball bearing stanchion fairleads and an additional block mounted

on the bow pulpit near the furling drum to lessen the chance of

a line foul due to a bad drum wrap. A

turning block was added to the roller furling termination at the

cockpit. It allows a fair lead for pulling up on the line (using

leg muscles)…much easier! This reefing line is led through added

ball bearing stanchion fairleads and an additional block mounted

on the bow pulpit near the furling drum to lessen the chance of

a line foul due to a bad drum wrap. |

Ever

wondered where the inspection port is for your starboard "watertight"

flotation compartment? If your boat is like ours, it is buried under

the carpet! You have to very carefully cut the carpet away with

a razor knife and the glue the edges down flush with the port. Having

done this, you can now inspect the compartment on occasion, as PCI

recommends. We are slowing filling up all four of ours with empty,

sealed up, plastic drink bottles…mostly one-liter water bottles.

That way, I know they will offer some flotation…I'm not so sure

otherwise! Ever

wondered where the inspection port is for your starboard "watertight"

flotation compartment? If your boat is like ours, it is buried under

the carpet! You have to very carefully cut the carpet away with

a razor knife and the glue the edges down flush with the port. Having

done this, you can now inspect the compartment on occasion, as PCI

recommends. We are slowing filling up all four of ours with empty,

sealed up, plastic drink bottles…mostly one-liter water bottles.

That way, I know they will offer some flotation…I'm not so sure

otherwise! |

I

think the area under the aft berths could do with a little ventilation.

We added these small louvered vents to the bulkheads in front of

each aft berth. I

think the area under the aft berths could do with a little ventilation.

We added these small louvered vents to the bulkheads in front of

each aft berth. |

As

items of preference, we added a gooseneck reading light, a Hella

fan, a Xintex CO detector, and a recessed 12v cigarette lighter

socket in each of the two aft staterooms. The main bunk and the

head also have CO detectors. As

items of preference, we added a gooseneck reading light, a Hella

fan, a Xintex CO detector, and a recessed 12v cigarette lighter

socket in each of the two aft staterooms. The main bunk and the

head also have CO detectors. |

A

simple safety addition is the install off a pair of short Teak handrails

to each corner of the saloon settee's backrests. A

simple safety addition is the install off a pair of short Teak handrails

to each corner of the saloon settee's backrests. |

All

tank levels can be monitored with the install of this tank gauge

system. It is fully electronic and non-invasive of the tanks. All

tank levels can be monitored with the install of this tank gauge

system. It is fully electronic and non-invasive of the tanks. |

For

boats with propane "demand" water heaters, the problem of keeping

a stable water temperature can be solved with the addition of temperature

regulating valve. It is mounted in the counter top just aft of the

sink and faucet. For

boats with propane "demand" water heaters, the problem of keeping

a stable water temperature can be solved with the addition of temperature

regulating valve. It is mounted in the counter top just aft of the

sink and faucet. |

Some

minor additions to the head can be seen here, including the shower

curtain track detail, vanity mirror, interior trim on hatch vents

and Xintex CO monitor. The adjacent picture shows a couple of stainless

towel bars/hand-holds. Some

minor additions to the head can be seen here, including the shower

curtain track detail, vanity mirror, interior trim on hatch vents

and Xintex CO monitor. The adjacent picture shows a couple of stainless

towel bars/hand-holds. |

A

Heart Inverter can be installed in a number of places. We put ours

as shown in the port "under bunk" area. The stock cables are exactly

long enough to reach the battery compartment. This is a fan-cooled

unit. In this location, no overheating problems have occurred in

three years of use. The same space contains the AC pump and filter. A

Heart Inverter can be installed in a number of places. We put ours

as shown in the port "under bunk" area. The stock cables are exactly

long enough to reach the battery compartment. This is a fan-cooled

unit. In this location, no overheating problems have occurred in

three years of use. The same space contains the AC pump and filter. |

With

the 105's kick-up rudders and the Sonic drive, we found it safer

and easier to beach the bows, rather than trying to go in close

"stern to" as the earlier classic models seem to favor. For this

activity, we With

the 105's kick-up rudders and the Sonic drive, we found it safer

and easier to beach the bows, rather than trying to go in close

"stern to" as the earlier classic models seem to favor. For this

activity, we  installed

a "diver's" boarding ladder on the bow. It is removable for storage

in the bow compartment. The mount is seen attached in one picture

and the other shot shows the ladder in place. installed

a "diver's" boarding ladder on the bow. It is removable for storage

in the bow compartment. The mount is seen attached in one picture

and the other shot shows the ladder in place. |

Since

the propane locker needs to have a hasp to secure it to make it

meet ABYC codes, we added the same hasps to the other two cockpit

lockers. Since

the propane locker needs to have a hasp to secure it to make it

meet ABYC codes, we added the same hasps to the other two cockpit

lockers. |

This

is another overall view of the UK Lazy Cradle. This

is another overall view of the UK Lazy Cradle. |

This

stern view shows that we carry our fenders and a Life Sling in a

hard container attached to the two added stainless rails that we

replaced the lifelines back there with. This

stern view shows that we carry our fenders and a Life Sling in a

hard container attached to the two added stainless rails that we

replaced the lifelines back there with. |

Our

port stern carries an added bracket that allows a small outboard

motor mount to be slid into place. We can then mount our dink engine

on it for an emergency propulsion source. It's not fast, but it

will get you into an anchorage or out of the ICW if the big engine

dies and you can't sail. Our

port stern carries an added bracket that allows a small outboard

motor mount to be slid into place. We can then mount our dink engine

on it for an emergency propulsion source. It's not fast, but it

will get you into an anchorage or out of the ICW if the big engine

dies and you can't sail. |

This

shot shows some detail on the cam cleat mounting for the tension

line used on the backstay. Also, the rudder control lines can be

made easier to pull with the addition of some handles made of schedule

40 PVC pipe. This

shot shows some detail on the cam cleat mounting for the tension

line used on the backstay. Also, the rudder control lines can be

made easier to pull with the addition of some handles made of schedule

40 PVC pipe. |

We

use the area on top of and adjacent to the fridge as our "nav" station.

This shot shows the radios (SSB & CB) with the GPS chart plotter,

power-data bracket for the back-up handheld GPS and Radar mounted

on a swing-out bracket that moves them into the window above the

helm when desired. Either GPS unit can supply NEMA data to the Autopilot

and both share the same Differential beacon receiver and externally

mounted antenna. We

use the area on top of and adjacent to the fridge as our "nav" station.

This shot shows the radios (SSB & CB) with the GPS chart plotter,

power-data bracket for the back-up handheld GPS and Radar mounted

on a swing-out bracket that moves them into the window above the

helm when desired. Either GPS unit can supply NEMA data to the Autopilot

and both share the same Differential beacon receiver and externally

mounted antenna. |

These

two views show SUNDOG's helm station. In one view the internal bracket

is shown with the Radar and GPS swung into the window to be seen

at the helm. We carry the usual AutoHelm autopilot and wind instruments,

but we use an Interphase Probe forward-looking sonar as our primary

depth sounder. We also carry an additional Humminbird depth and

"fish finder" that is surface mounted inside the other hull away

from the Probe. The clinometer's mounting is above the autopilot

control head. These

two views show SUNDOG's helm station. In one view the internal bracket

is shown with the Radar and GPS swung into the window to be seen

at the helm. We carry the usual AutoHelm autopilot and wind instruments,

but we use an Interphase Probe forward-looking sonar as our primary

depth sounder. We also carry an additional Humminbird depth and

"fish finder" that is surface mounted inside the other hull away

from the Probe. The clinometer's mounting is above the autopilot

control head. |

The

antenna "farm" mounted on the aft rail includes the GPS, Citizen's

Band Radio (useful in the Bahamas) and the Differential Beacon receiver. The

antenna "farm" mounted on the aft rail includes the GPS, Citizen's

Band Radio (useful in the Bahamas) and the Differential Beacon receiver. |

We

added a small closure hasp on the rudder lockers. We

added a small closure hasp on the rudder lockers. |

This

overall view of the main stateroom shows a removable overhead bunk

compass that also is used mounted on the RDF receiver for obtaining

a radio bearing. The little color TV and VHS video tape player also

utilize a large swing mount to hold them. This

overall view of the main stateroom shows a removable overhead bunk

compass that also is used mounted on the RDF receiver for obtaining

a radio bearing. The little color TV and VHS video tape player also

utilize a large swing mount to hold them. |

|

There are

a few things you can do to optimize the performance of the Dometic

fridge:

(3) Add an internal 12v blower to circulate the air inside the box and point it at the fins at the back of the box. (Right) (4) using copper or aluminum screen scraps, cover all the vents with screen. If you don't do this immediately, you will get critters (even rats!) inside your boat for crew. |

|

Some more "data" for those going to a larger alternator:

|

|

The Pelican Hooks enable easier access from a parallel dock, as they create a large side "gate" at the cockpit. The Pelican Hooks are designed to be swaged on, but in this use, I simply chased out and tapped the barrel of the swage fittings to RH 1/4-28 thread so it would screw up on the remaining threaded stud on the lifelines after the existing turnbuckles were removed. (tip: use a "bottom tap") For proper adjustment, it was also necessary to cut about 1" off the threaded stud before installation. I installed with Locktite 242 on the stud's threads. To complete the project, a pair of stainless "stop" collars needs to be clamped on each lifeline just aft of the first stanchion to maintain the tension in the forward section of each life lines when the new side "gates" are opened. The clamp on collars are from McMaster-Carr (404-346-7000), part #6436K9. |

|

|

|

- Rob Hoffman, SUNDOG #551